- English

- Español

- Português

- русский

- Français

- 日本語

- Deutsch

- tiếng Việt

- Italiano

- Nederlands

- ภาษาไทย

- Polski

- 한국어

- Svenska

- magyar

- Malay

- বাংলা ভাষার

- Dansk

- Suomi

- हिन्दी

- Pilipino

- Türkçe

- Gaeilge

- العربية

- Indonesia

- Norsk

- تمل

- český

- ελληνικά

- український

- Javanese

- فارسی

- தமிழ்

- తెలుగు

- नेपाली

- Burmese

- български

- ລາວ

- Latine

- Қазақша

- Euskal

- Azərbaycan

- Slovenský jazyk

- Македонски

- Lietuvos

- Eesti Keel

- Română

- Slovenski

- मराठी

- Srpski језик

What types of dust collectors are suitable for welding work?

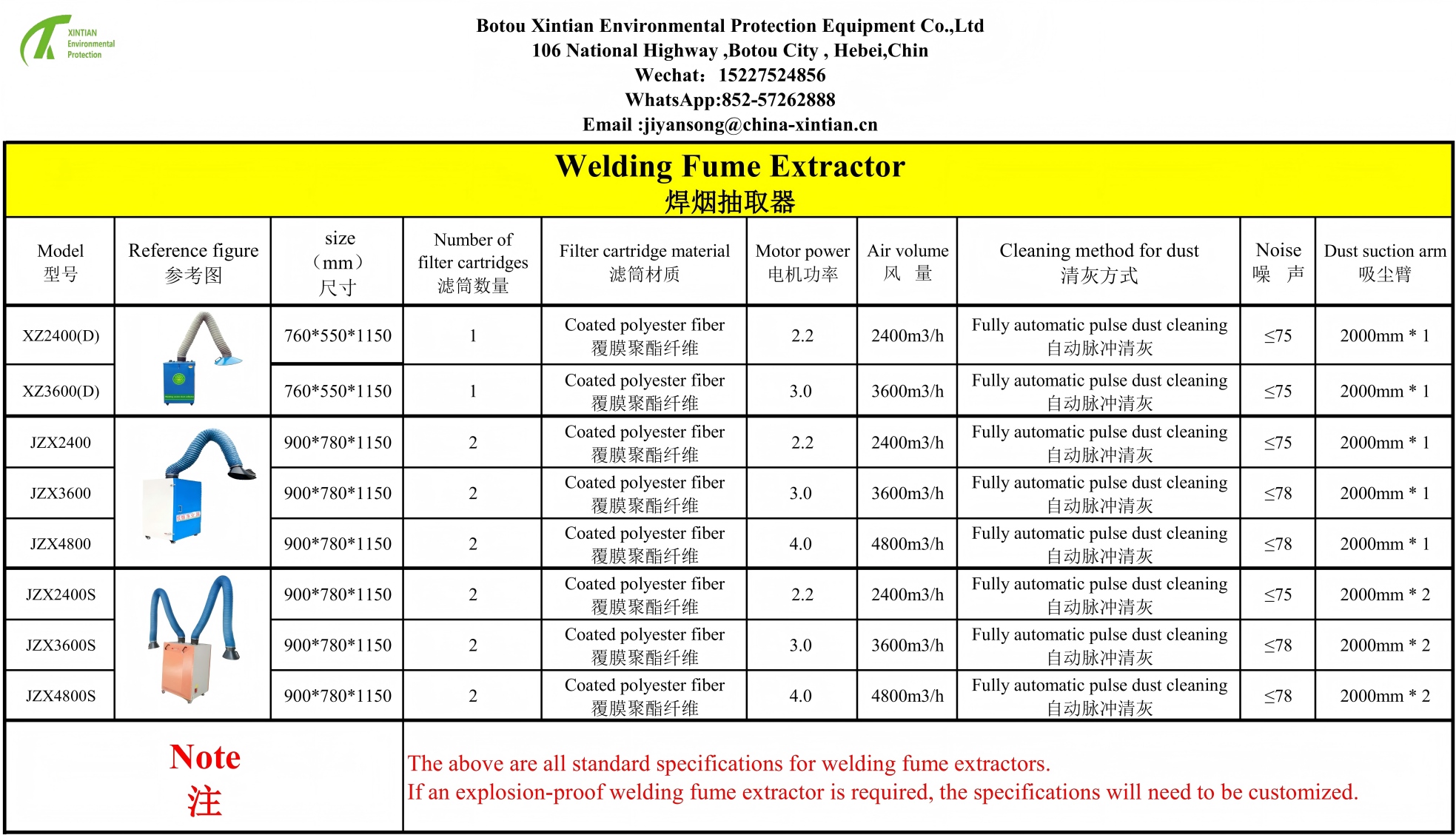

Botou Xintian Environmental Protection Equipment Co., Ltd. manufactures welding fume dust collectors specifically for welding workers, offering excellent quality at a reasonable price.

Depending on the limitations of the welding scenario, the appropriate dust collector needs to be tailored accordingly. The mainstream options include mobile cartridge dust collectors and centrally integrated dust collection systems.

1. Mobile Cartridge Dust Collector

The equipment is the first choice for small, discrete welding operations and is suitable for manual arc welding in auto repair shops and small metal processing shops. It features casters and an omnidirectional suction arm of 2-3 meters, allowing 360° rotation and precise positioning of the weld point to capture smoke. It's plug-and-play and doesn't require complicated installation. The filter element with anti-static film coating has a retention efficiency of more than 99% for metal particles larger than 0.1μm. It also has a pulse jet cleaning system for automatic cleaning of the filter media.

2. Centralized Integrated Dust Collection System

Suitable for robotic automated welding production lines and large-scale welding workshops with multiple fixed workstations, such as automotive body-in-white welding lines and large component welding production lines. The system installs fixed dust collection hoods or suction arms at each workstation, and collects the fumes and dust through a pipeline network to a central unit for processing. The main unit is often paired with explosion-proof cartridge or baghouse dust collectors. Cartridge filters are suitable for filtering fine dust generated during welding; if the dust volume is large (requiring an air volume of over 10,000 m³/h), baghouse filters are more suitable and have lower maintenance costs.