In this blog, we explore the critical role of a Cyclone Dust Collector in maintaining a clean and efficient workshop environment. From understanding its mechanism to choosing the right model, we cover everything you need to know. We also highlight Xintian's innovative solutions for optimal dust collection.

Table of Contents

- Introduction to Cyclone Dust Collectors

- How Does a Cyclone Dust Collector Work?

- What Are the Benefits of Using a Cyclone Dust Collector?

- Which Types of Cyclone Dust Collectors Are Available?

- How to Install a Cyclone Dust Collector?

- Why Is Maintenance Important for Cyclone Dust Collectors?

- Cyclone Dust Collector vs. Other Dust Collection Systems

- Frequently Asked Questions (FAQ)

Introduction to Cyclone Dust Collectors

A Cyclone Dust Collector is a high-efficiency device designed to separate dust and debris from the air in industrial and workshop environments. Xintian, a leading brand in dust collection solutions, offers state-of-the-art cyclone collectors that ensure a cleaner, safer workspace. These systems are essential for woodworking, metalworking, and other industries where airborne particles can pose health risks or equipment damage.

How Does a Cyclone Dust Collector Work?

Cyclone dust collectors operate on the principle of centrifugal force. Dust-laden air enters the cyclone chamber at a high velocity, spinning in a vortex pattern. Heavier particles are thrown toward the walls of the chamber and fall into a collection bin, while cleaner air exits through a central exhaust. This mechanism provides highly efficient dust separation without clogging filters.

- Airflow enters tangentially to create a spinning motion.

- Dust and debris are forced outward by centrifugal force.

- Clean air exits through the top of the cyclone.

- Collected dust drops into a bin for easy disposal.

What Are the Benefits of Using a Cyclone Dust Collector?

Investing in a Cyclone Dust Collector from Xintian provides multiple advantages for your workshop or industrial facility:

| Benefit | Description |

|---|---|

| High Efficiency | Removes up to 99% of dust and debris from the air, reducing health risks. |

| Low Maintenance | Minimal filter clogging due to the centrifugal separation method. |

| Cost Savings | Reduces cleaning labor and prolongs the lifespan of equipment and filters. |

| Improved Air Quality | Creates a safer and more comfortable working environment. |

| Versatility | Suitable for woodworking, metalworking, plastics, and other industries. |

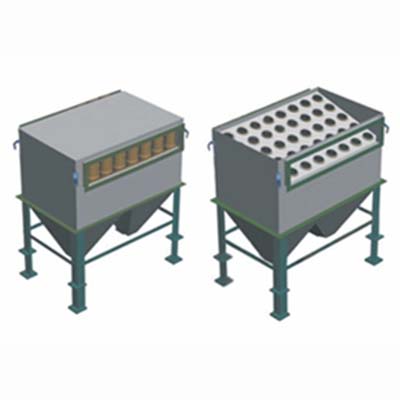

Which Types of Cyclone Dust Collectors Are Available?

Cyclone dust collectors come in different designs and configurations. Choosing the right type depends on your workspace size, material types, and airflow requirements. Common types include:

- Single-Cyclone Collectors: Suitable for small workshops, easy to install.

- Multi-Cyclone Collectors: Ideal for industrial applications, higher efficiency.

- Portable Cyclone Units: Compact and mobile for temporary or changing setups.

- High-Volume Cyclones: Designed for heavy-duty operations with continuous airflow.

How to Install a Cyclone Dust Collector?

Proper installation is crucial for optimal performance. Follow these steps to set up your Xintian Cyclone Dust Collector:

- Select a stable location close to dust-generating machines.

- Assemble the cyclone according to the manufacturer's instructions.

- Connect ducting securely to each machine.

- Ensure proper airflow direction and minimal bends in ducts.

- Test the system and adjust if necessary for maximum efficiency.

Why Is Maintenance Important for Cyclone Dust Collectors?

Regular maintenance ensures your cyclone dust collector performs at peak efficiency and extends its lifespan. Key maintenance tasks include:

- Emptying the dust bin frequently.

- Inspecting and cleaning cyclone walls and ducts.

- Checking for air leaks in ducting and seals.

- Monitoring airflow and pressure for consistent performance.

- Replacing worn components promptly to avoid downtime.

Cyclone Dust Collector vs. Other Dust Collection Systems

Compared to bag filters or cartridge collectors, cyclone dust collectors offer several advantages:

| Feature | Cyclone Dust Collector | Bag/Cartridge System |

|---|---|---|

| Filter Clogging | Minimal | Frequent cleaning required |

| Maintenance Cost | Low | High |

| Efficiency | High for coarse dust | Effective for fine dust |

| Lifespan | Long-lasting | Shorter without replacement |

Frequently Asked Questions (FAQ)

1. What size cyclone dust collector do I need?

Size depends on the airflow requirement of your machines and the type of dust generated. Xintian provides a sizing guide to help you choose the right model.

2. Can I install a cyclone collector myself?

Yes, many models are designed for DIY installation, but professional assistance may be recommended for larger industrial systems.

3. How often should I empty the dust bin?

It depends on usage, but generally, empty the bin when it is two-thirds full to maintain optimal efficiency.

4. Are cyclone dust collectors noisy?

Noise levels vary by model, but Xintian units are engineered to minimize sound while maintaining strong airflow.

5. Can a cyclone collector handle fine dust?

Cyclones are most effective for coarse and medium dust. For very fine dust, a secondary filtration system may be necessary.

If you want to improve your workshop air quality, reduce maintenance costs, and enhance safety, investing in a high-quality Cyclone Dust Collector from Xintian is the smart choice. Contact us today to find the perfect solution for your facility!